Process

The site operations team, ISS Engineering, had been increasingly harvesting parts from controllers and control panels on non-critical systems to repair controllers serving critical systems.

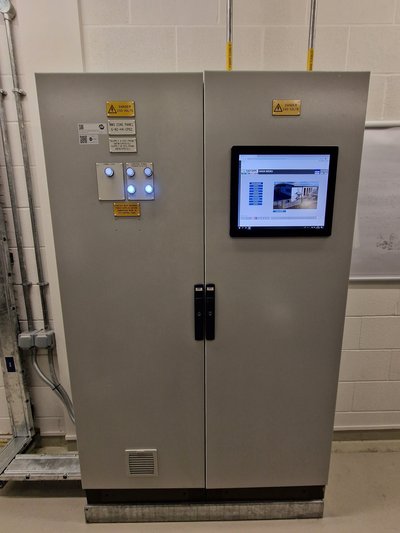

The output of the investigations provided a series of recommendations on the upgrade options for the system, and improvements to the systems resilience model. Schnieder’s 731 TAC Xenta controllers were deemed as a business risk and Team BMS were instructed to replace them. An open protocol bacnet solution was developed, that could communicate with the site wide EMS/PMS systems and provides the client with overall control and monitoring of their critical systems.

Throughout the project we carried out vigorous Factory Acceptance Testing, proving points within our new software prior to replacing old systems and commissioning. During the FAT, a test rig was used to connect to a screen showing our new BMS headend graphic. We proved that the software was functioning correctly by simulating failures as part of an in-depth review by the projects commissioning manager before installation. Once installed, each subnet was witnessed back to the client for a site acceptance test and subsequently handed over.